Metal casting and forging are fabrication techniques used to produce many types of metal components. In metal forging, thermal and mechanical energy is applied to steel ingots or billets while in a solid state to achieve the desired shape. Metal casting, in comparison, requires materials to be heated to a molten or liquid state. They are then poured into a vessel or mold where they cure to produce the end component.

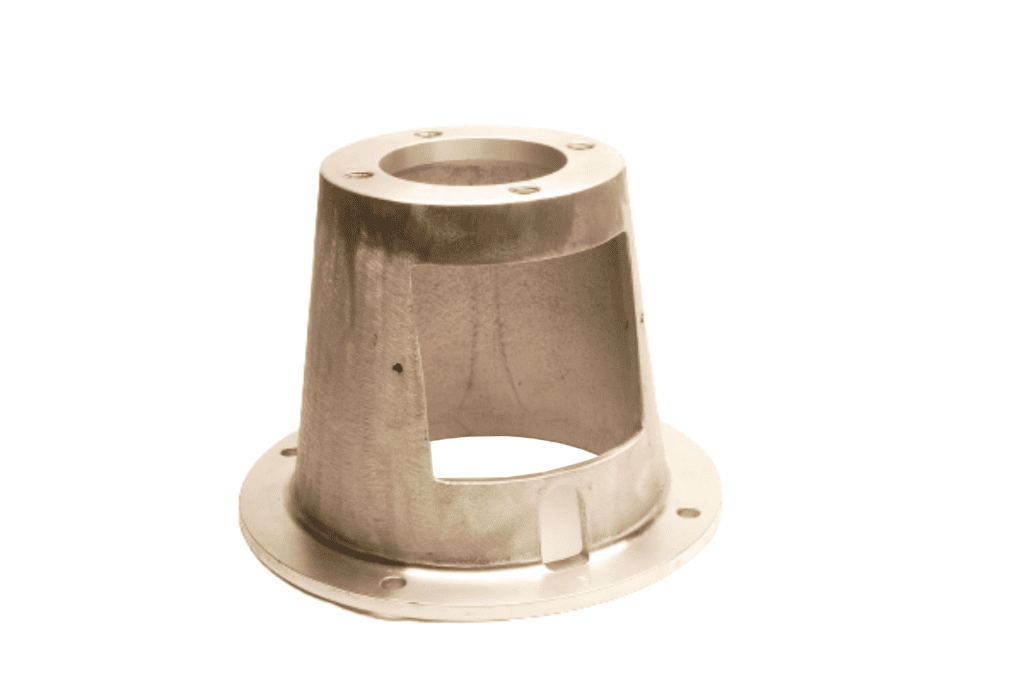

Integrated Solutions is a trusted supplier of OEM cast parts that feature complex shapes and meet precise tolerances and hardness requirements. ISI creates custom molds according to design criteria and provides efficient production services backed by a full warranty. Our extensive metal fabrication capabilities allow us to meet the demands of nearly any type of part production. Our most popular services include mass part production using die-cast molding for smooth or textured and plated components, as well as sand casting, gravity injection, and lost wax casting.

Casting and Forging Capabilities

At ISI, we offer a comprehensive selection of casting and forging services for many types of alloys. Our experts can help you identify the most successful and cost-effective fabrication process for your project. The metal casting processes we offer include:

- Custom Die Casting / Custom Metal Casting: This manufacturing process uses custom-produced molds that are injected with liquid metals at high pressure. The metal cools, creating perfectly customized parts and components. Custom die casting produces large numbers of products cost-effectively.

- Custom Investment Casting: In this fabrication method, molten metal is poured into a disposable ceramic mold. After the metal cools, the ceramic shell is removed. Investment casting produces highly detailed parts that don’t require extensive finishing.

- Lost Wax Casting: Lost wax casting involves pouring hot metal into a wax model to create components that can be simple or complex. This process is used to create exact replications of existing components by submerging the component in wax to create the mold. Similar to investment casting, this process can produce parts requiring tight tolerances.

- Permanent Mold Casting: This type of casting uses reusable molds, typically made from metal. It is commonly used for high-volume production runs of small metal components featuring uniform wall thicknesses.

- Custom Metal Molds: Nearly any type of product can be created from custom metal molds. A diverse selection of materials can be used in the production process, including many metals and metal alloys, glass, concrete, and plastic.

- Gravity Casting: Used with non-ferrous alloy parts, gravity casting involves pouring molten metal into a mold from a crucible. Metal dies or sand molds are used without the use of centrifugal force, vacuums, or pressurized gases.

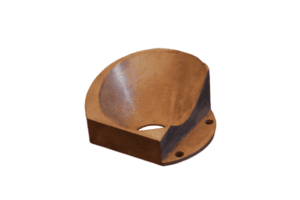

- Sand Mold Casting: This ancient casting process uses sand to create a non-reusable mold. A variety of molten metals can be used to create components using this method.

- Lost Foam Casting: Used to create complex metal pieces, lost foam casting involves a foam mold that evaporates when it comes into contact with molten metal. The foam mold is held into place using sand.

- Spin Casting: This casting manufacturing process utilizes a mold that spins on a central axis until the molten metal inside it solidifies. In this method, centrifugal force is used to pull the metal into all of the mold’s cavities.

- Die-cast Magnesium: Die-cast magnesium is ideally suited for lightweight components featuring thin walls. It provides an excellent strength-to-weight ratio, is fully recyclable, and is corrosion-resistant.

Materials

ISI expertly crafts forged and cast components from an extensive selection of casting metals, including:

- Aluminum

- Brass

- Bronze

- Carbon steel

- Cast iron

- Stainless steel

- Magnesium

- Titanium

Applications and Industries

Metal casting and forging are used to produce components vital to numerous diverse industries. ISI provides solutions for industries such as:

- Aerospace

- Automotive

- Construction

- Drilling

- Electronics

- Food processing

- Hardware

- Mining

Metal Casting and Forging Capabilities at Integrated Solutions

ISI provides comprehensive metal casting services for both large and small production runs. We deliver precise components that meet all end-application performance requirements. Our team can develop a custom mold from your design and provide cost-effective production using the most suitable method for your application.

Contact us today to learn more about our casting and forging services. When you’re ready to get started on a personalized solution, request a quote.